I have had a lot of experience with launching dollies. Aluminum tubing seems to work the best. No rust problems. Plastic axles for the wheels for the same reason. Stainless Steel bolts/washers/nuts. I have gotten more than ten years out of Redwing’s dolly, and it is still going strong.

Gwragedd Annwn is 14’6″ long, too long to use “Redwings” launching dolly. At 225 pounds, (102 kg.) I can use the same basic design as “Redwings” dolly, using 1½” square aluminum tubing, and 1″ solid round bar as the axle. This will be a basic “T” shaped dolly. The most critical part is getting the balance of Gwragedd Annwn on the dolly right. Too far forward of the axle and the dolly is heavy to lift. Too far aft of the axle and the boat will tip the dolly backwards and fall off.

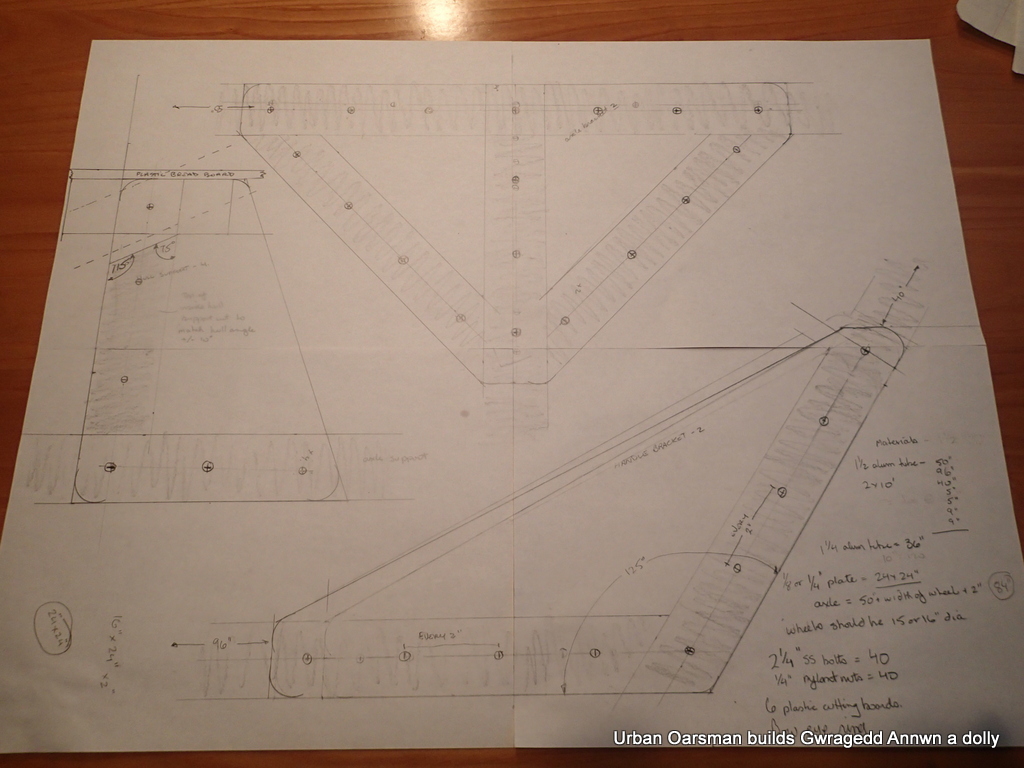

The first step is to design the support brackets:

The Urban Oarsman builds a dolly for Gwragedd Annwn

These are the brackets for the axle, the bow mast and the hull side supports. The stainless steel bolt positions are marked. I head to the metal supermarket and buy enough aluminum bar for the axle, axle supports, the centre piece and the mast piece and enough aluminum ⅛” plate for the support brackets.

I measure Gwragedd Annwn to find where the balance point is. This gives me the distance from the mast to the axle.

Using the plans as a template, with my jigsaw and a metal cutting blade, I cut out the support brackets and cut the square tubing to length. I use a drill press for the ss bolt holes in the brackets. I dry-fit the pieces together and drill all of the ss bolt holes through the aluminum bar. Photo of the partly-assembled dolly:

Bow mast of the dolly. The bottom of the mast is cut at an angle to match the ground.

Here the bow mast is clamped to the dolly frame, ready for drilling.

Rear axle, ready to put in the square tube supports. I am using the support brackets as a template.

The plastic-hubbed wheels (no metal to rust) are on a 1″ diameter rod, which is in a 1¼” piece of square aluminum tubing which is in the 1½” diameter square aluminum tubing. The 1¼” tubing fits neatly into the 1½” tubing and the 1″ diameter rod fits neatly into the 1¼” tubing. This assembly is “locked” by ss bolts going through all three pieces. A cotter pin and washer (cut from the aluminum plate) secure the wheel on.

Only a few more pieces to assemble. Note the cotter pin and washer.

After installing the axle supports, I put on the UHD plastic hull supports.

UHD plastic supports also know as “bread boards”.

I drill a 1″ hole at the top of the mast for a handle. The handle is a piece of 1″ aluminum rod. A bow ring holds the handle in place. A plastic cap finishes the handle assembly off.

Mast assembly.

Time to go and try the dolly out.

The dolly as delivered to HSC. The axle supports are bolted in and I have replaced the bread boards with some ½” UHD plastic sheeting. I also cut off all of the protruding bolt ends flush with the nylon nuts.

Another view:

Ready to go!

Trying the dolly out:

Bringing Gwragedd Annwn onto her dolly for the first time.

After a few launches, I find that there are better ways to do some things:

First modification, covering the Axle assembly bolt caps.

Gwragedd Annwn snaps off one of the “V” shaped keel guides. I design new ones:

New keel guides and axle joint bolt protector plate.

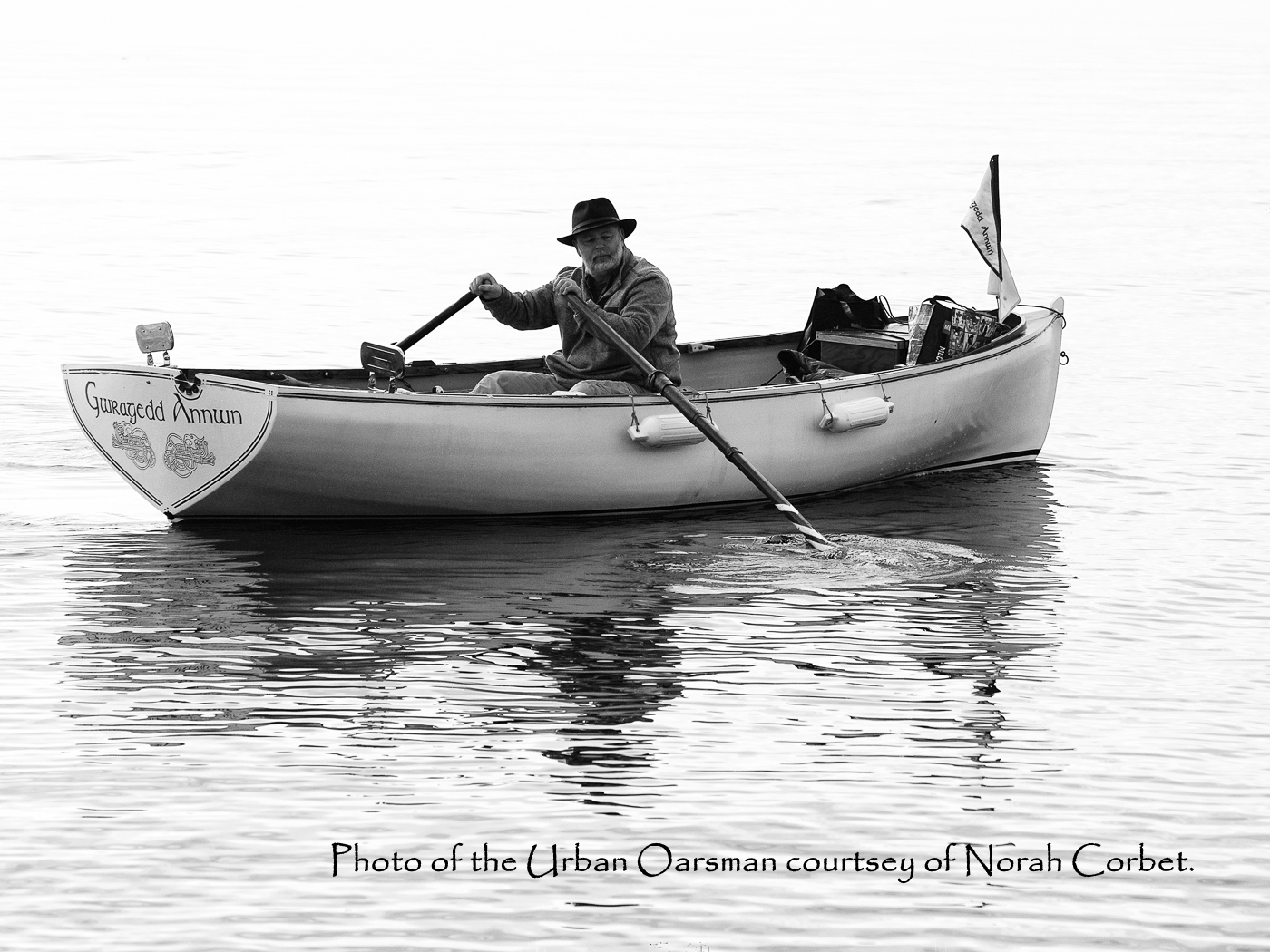

A few photos of Gwragedd Annwn with her dolly:

Gwragedd Annwn on her dolly, top of the ramp at the HSC.

Gwragedd Annwn on her dolly in her storage spot at HSC. Ready to go rowing!

Going to Burnaby Lake, transferring from road trailer to dolly. I had put Gwragedd Annwn on her road trailer backwards, hoping to make the transfer to the dolly easier.

Launching into Still Creek, going to Burnaby Lake.

Returning from Burnaby Lake.

Deer Lake afternoon launch. The dolly is atop her hull. Being backwards or forwards on her road trailer does not seem to make the transfer to the dolly any easier.

Launching into Deer Lake. Notice how the bottom of the dolly mast digs into the sand.

Tight fit between the Deer Lake bollards!

Back home at HSC.

Over all the dolly has been a success.

Good rowing to you,

Mike