Weekend three of the Canoe Build:

A bit of a change, Paul came up on Saturday to work on the canoe.

I have a prior rowing trip with the Hollyburn Sailing Club, the “Winter Hot Wine Paddle”, from the Hollyburn Sailing Club to Sandy Cove in West Vancouver, B.C., so Paul continues on his own, shaping the stems to accept the bead and cove planking.

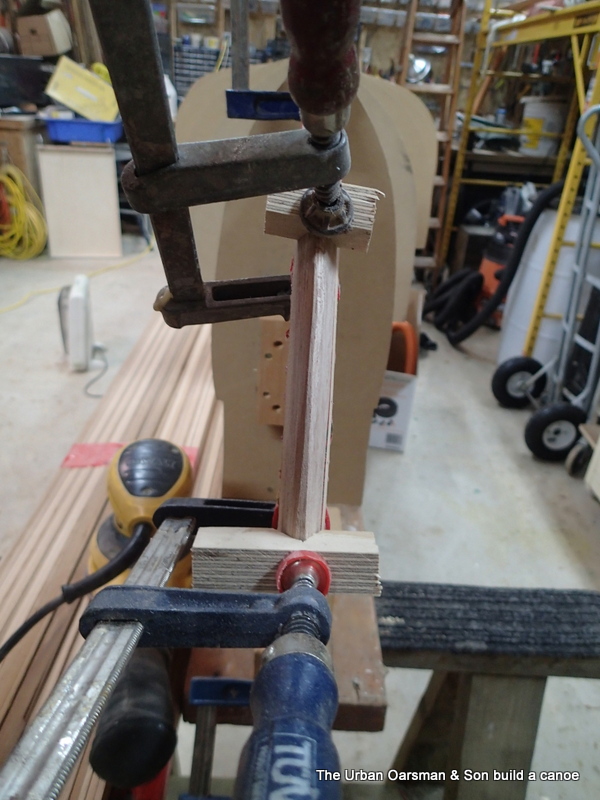

Using a disk sander with coarse-grit sand paper, Paul shapes the stem pieces for the planking.

Note that Paul is sanding down the form as well to get the correct angle for the planking.

The job goes reasonably quickly.

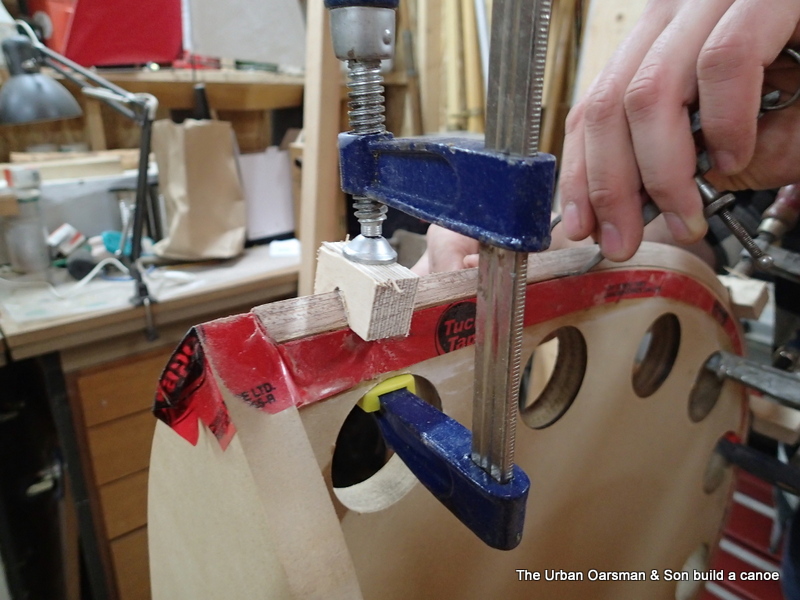

Small angle blocks hold the stem in place for shaping. Using a caliper to insure the stem is even on both sides of the canoe.

Looking pretty good!

After shaping the stem, When I get home, Paul and I then put the “bead” on the planking. We make up a jig using a router, a “bead” routing bit, the shop-made extension table for the Shopsmith and two feather boards. This will be a two-man job. The strips are too long for one person to handle safely.

Shop-made jig for putting the “bead” onto the strips.

To make the fence, I “routed” the bead bit into the fence at the correct height to put the “bead” on the centre of the strip. The top feather-board holds the strip down. the side feather-board hold the strip to the fence. The shop-vac hose sucks up most of the sawdust.

The jig in action. The green object in the centre is the “bead” router bit. The fence almost completely covers the bit, just leaving enough exposed to put the right amount of “bead” onto the strips.

Now it is just a matter of Paul feeding the strips in and I pulling the strips through. We have 62 strips to do.

About ⅔ to go for one bundle of strips.

The strips have been sorted as to colour…and numbered…We keep them in order so both sides of the canoe will look similar.

Keeping the strips in order…Making the numbers more visible.

Two bundles of strips with a “bead” edge.

Next Step: Putting a cove edge onto the strips. We will have to adjust the jig, replacing the “bead” bit with the “cove” one, adjusting the bit height, and the feather boards. Getting closer to planking with every step.

Good rowing (maybe good paddling) to you,

(Pogies for when the rowing is cold!)

The Urban Oarsman rows in the Hollyburn Sailing Club Winter Hot Wine Paddle with a friend. December 16th, 2017.

Mike